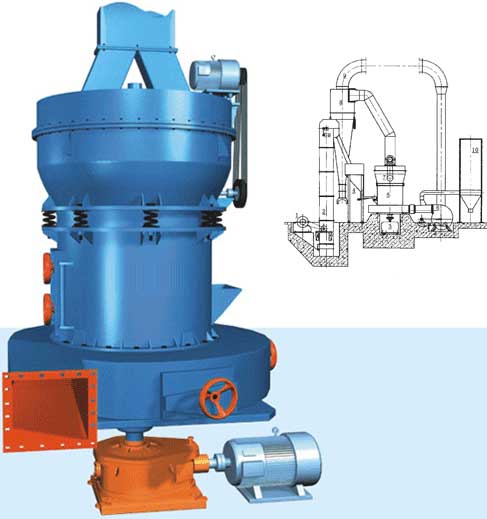

Raymond mill

Discription of of Raymond mill

The machine is used for grinding the barite, limestone, kaolin, cerames, ahd slags, etc, below scale 9.3 of Mohs hardness and 280-odd sorts of non-inflammable and non-explosive stuff in the trades of mining, metallurgical industrial, chemical engineering and building material for high fine powder generation and processing. The product size is adjustable in the range of 80-325 (600 the largest) meshes. It is possible to product 30-80 mesh coarse powder through special device in the machine.

Features of of Raymond mill

1,The whole plant is a vertical structure of strong systematic characteristic, so it occupies small area. From crushing of raw material to grinding and packing is an independent production system. 2,Compared with other milling plants, its passing ratio achieves 99%, this is what other mill can not reach; 3,Driving system of main frame adopts airtight gearing and pulley, drives smoothly and operates reliably, 4,Main parts of the whole plant are made from cast and steel of high quality. The technics is so subtly that insures the durability of whole plant, 5,The electric control system is centralized controlled, so the automaticity is high, no people are needed in the operating room.

Working principle of of Raymond mill

In the main frame, a 100-1500 kg powered pressure spring is fixed to the roller suspender. After the grinder is put into effect, the roller rotates around the main shaft, and rolls closely against the ring pressed by the high pressure spring and centrifugal force. And its rolling pressure ration is 1.2 times higher than that of the Raymond grinder under the same power condition and the production output is raised to substantial degree.

When a certain degree of wear of roller and ring is affected, it is recommended to adjust the length of the spring to maintain the constant pressure between the roller and the ring. As a result, the stable output and fineness are ensured.

Main Technical parameters of Raymond mill

| Type | 6R4525 | 5R4119 | 4R3216 | 3R3016 4R3016 | 3R2715 4R2715 | 3R2615 | 3R2115 | 3R60 |

| Particle size of feed (mm) | <=30 | <=25 | <=25 | <=25 | <=20 | <=20 | <=15 | <=15 |

| Particle of finished product(mm) | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 |

| shift output at different material fine degree | 16-120 | 8-60 | 4-45 | 3-35 | 2-28 | 1.5-20 | 1-18 | 0.5-8 |

| Rotate speed if sentral shaft (r/min) | 82 | 105 | 130 | 160 | 160 | 160 | 180 | 280 |

| Inner diameter of pulverzing ring (mm) | 1620 | 1270 | 970 | 880 | 830(800) | 780 | 650 | 410 |

| Diameter of pulverzing roller(mm) | 450 | 410 | 320 | 300 | 270 | 260 | 210 | 140 |

| Height of pulverizing ring(mm) | 250 | 190 | 160 | 160 | 150 | 150 | 150 | 100 |

| Electrical machine of main frame | y315m-4-32 | y280s-4-75 | y225s-4-37 | y225m-8-30 | y225m-8-22 | y225s-8-18.5 | y200L-8-15 | y160m-6-7.5 |

| Electrical machine of blower | y315m-4-132 | y250m-4-75 | y200L-4-37 | y180m-4-22 | y160L-4-15 | y160L-4-15 | y160m-4-11 | y132s-2-5.5 |

| Electrical machine of analyzer | y160m-4-11 | yc200-4B-7.5 | yc120-4A-5.5 | y112m-6-2.2 | y112m-6-2.2 | y112m-6-2.2 | y112m-6-2.2 | y90L-6-1.1 |

Copyright © 2010 Zhengzhou Taida Company. All Rights Reserved. Tel:0086-18539990967 Fax:86-371-86565118

E-mail:vip@tdaxy.com Address: National University Science&Technology park, High and New Technology Development Zone, Zhengzhou city, Henan Province